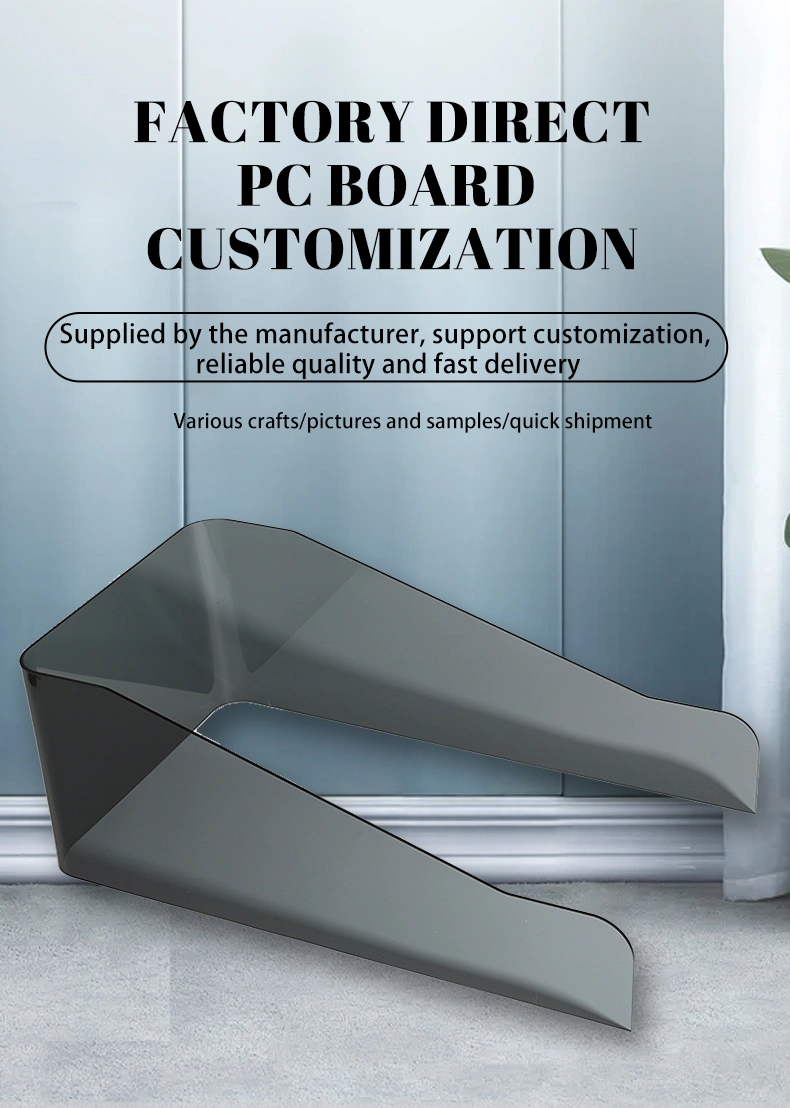

Product information

|

Product name |

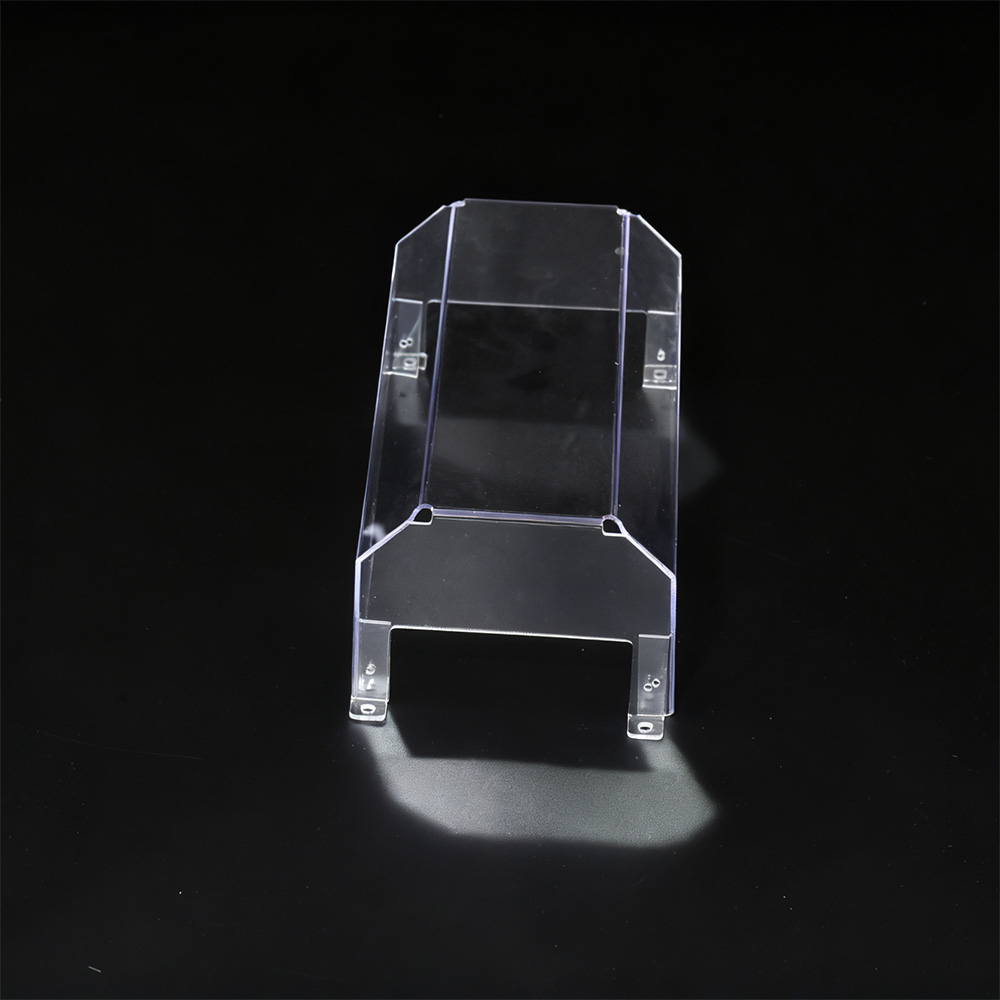

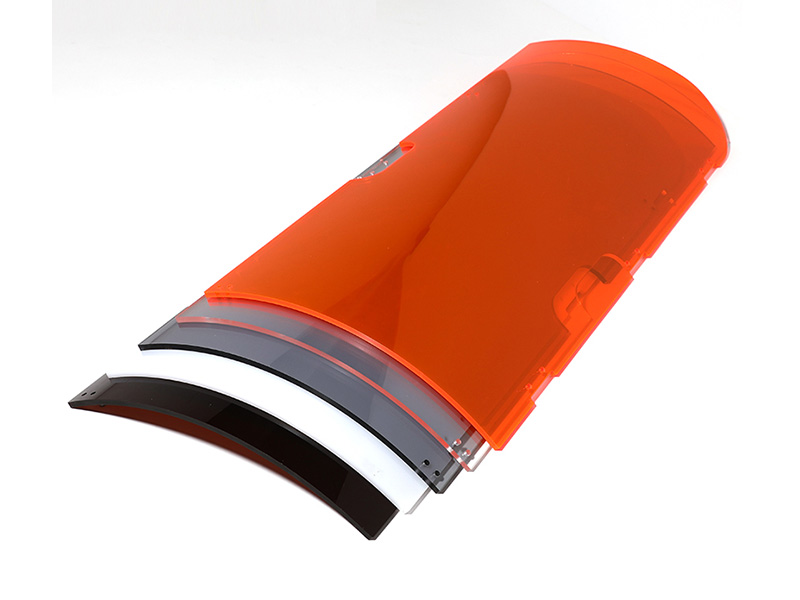

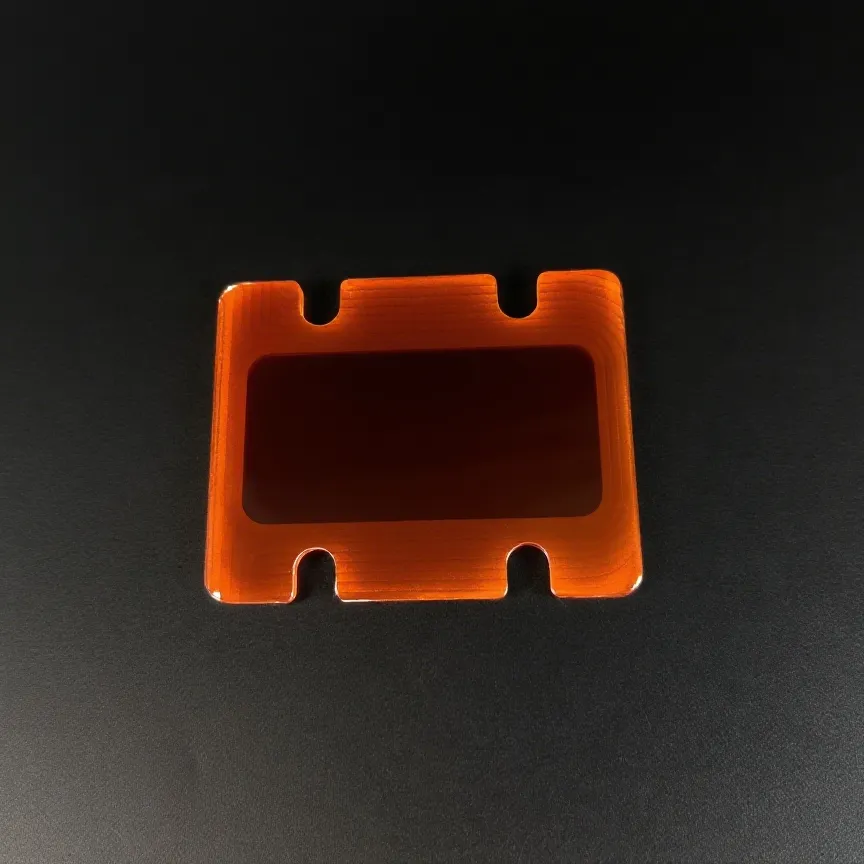

Equipment Protective Cover |

|

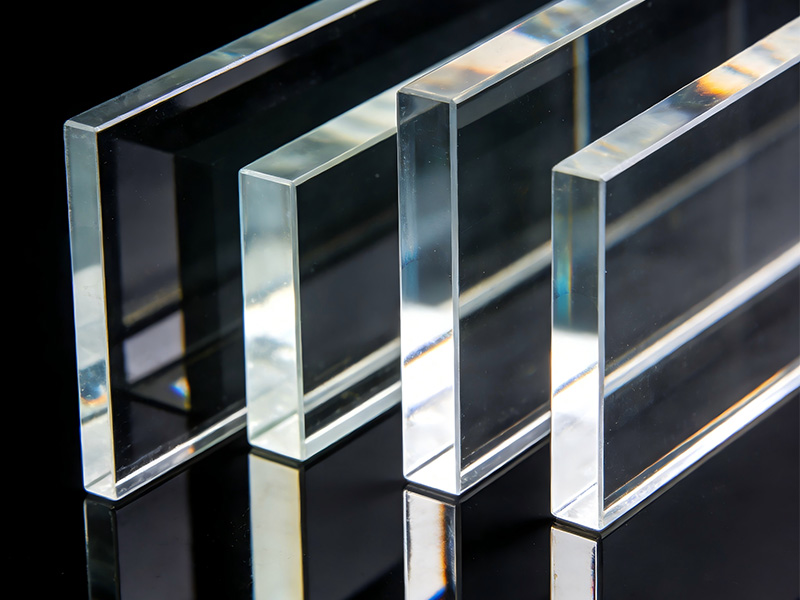

Product size |

Made-to-Order Size; Thickness: 2mm (Customizable Thickness) |

|

Product color |

Transparent, white, black, custom colors |

|

Material |

Polycarbonate(PC) |

|

Custom |

Drawing to sample/custom size/thickness |

|

Application |

Building skylights, car lamp covers, industrial protective shields, electronic device housings |

|

Feature |

High impact resistance, excellent weather resistance, high light transmittance, wide temperature range |

|

Physical properties |

Density: ~1.2g/cm³; Impact strength: 600-800J/m; Light transmittance: 88-90%; Working temp: -40~120℃ |

|

Chemical properties |

Flame retardancy, chemical corrosion resistance, etc. |

|

Others |

Flame retardant (UL94 V-0 grade), antistatic (custom),UV-resistant(custom) |

|

Surface |

Smooth transparent/Frosted |

|

Fabrication Process |

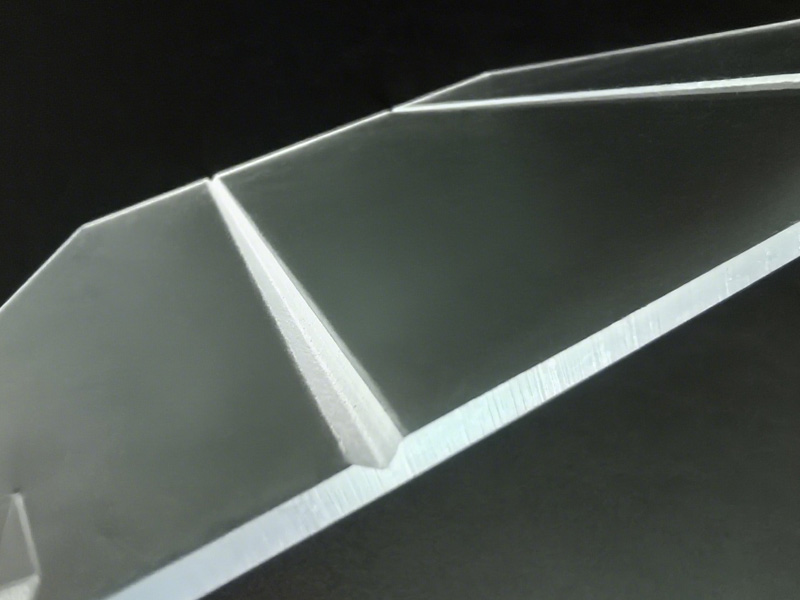

Cutting,Cold Bending |

Technique

Production Processe

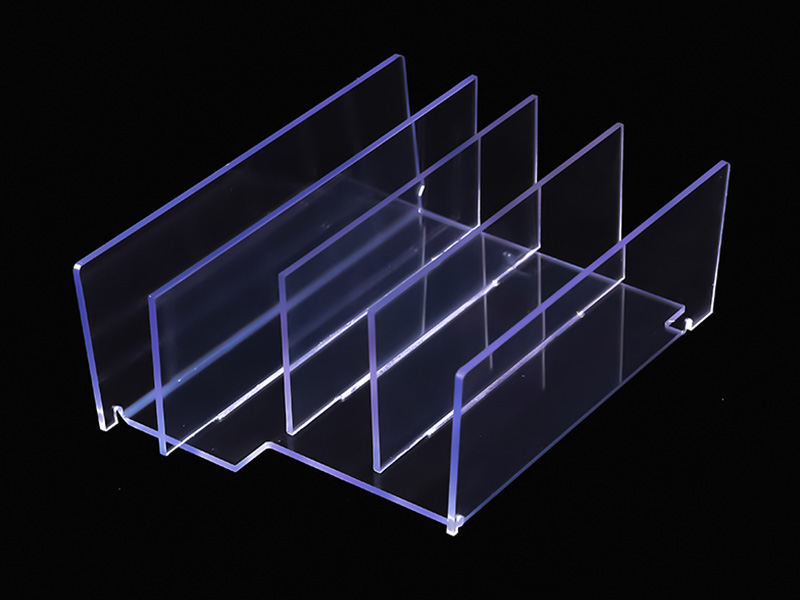

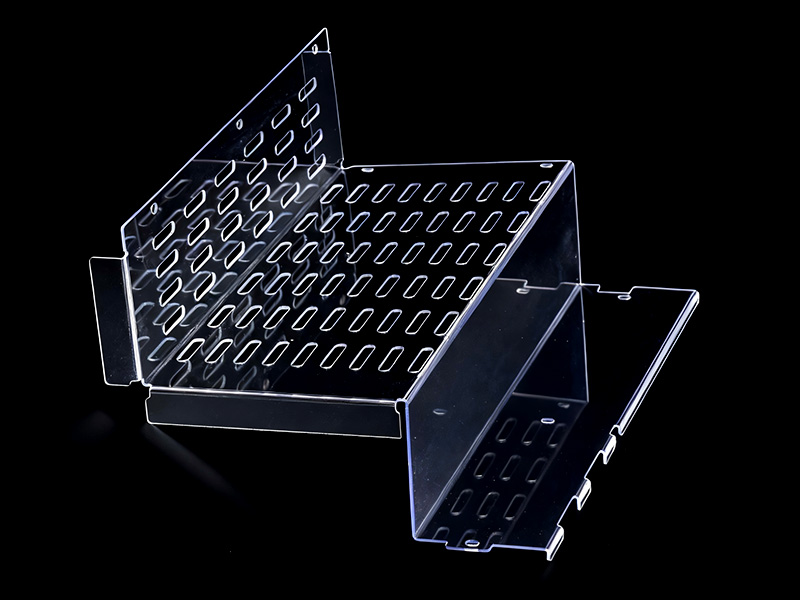

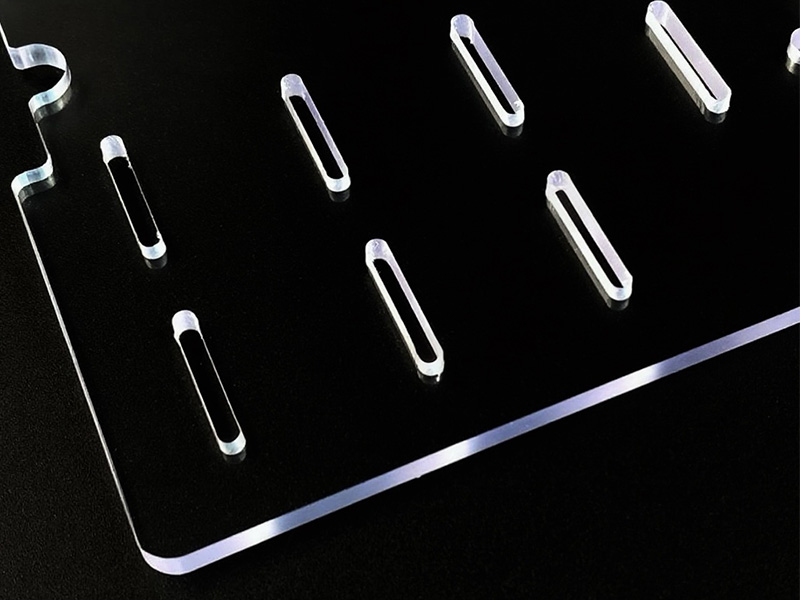

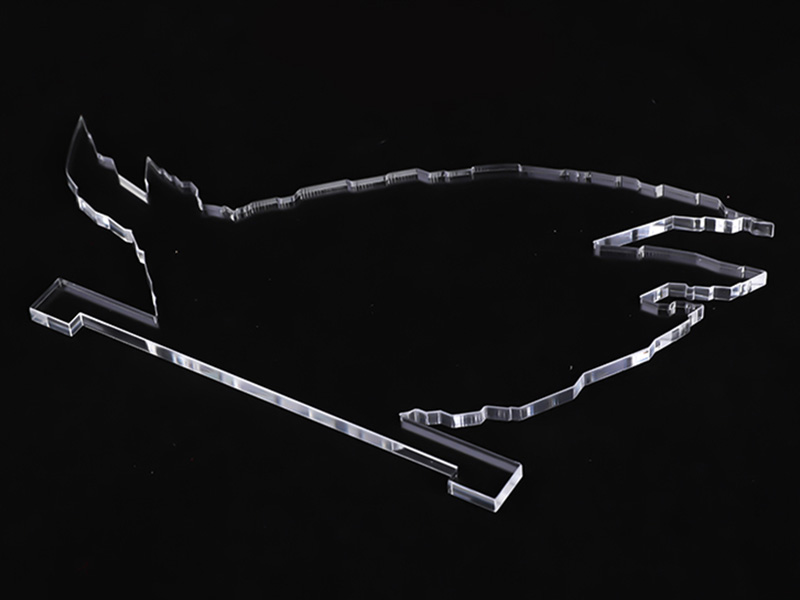

We can independently undertake the process of cutting, undercutting, milling, slotting,unching,countersinking,beveling, chamfering,brightness polishing, bending andbonding of acrylic sheet, plexiglass,PC sheet, pe sheet and pvc sheet.

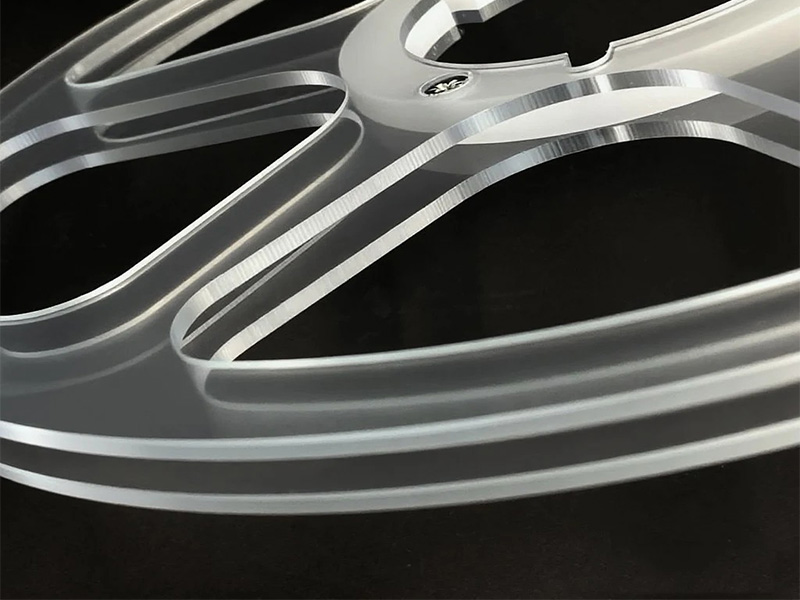

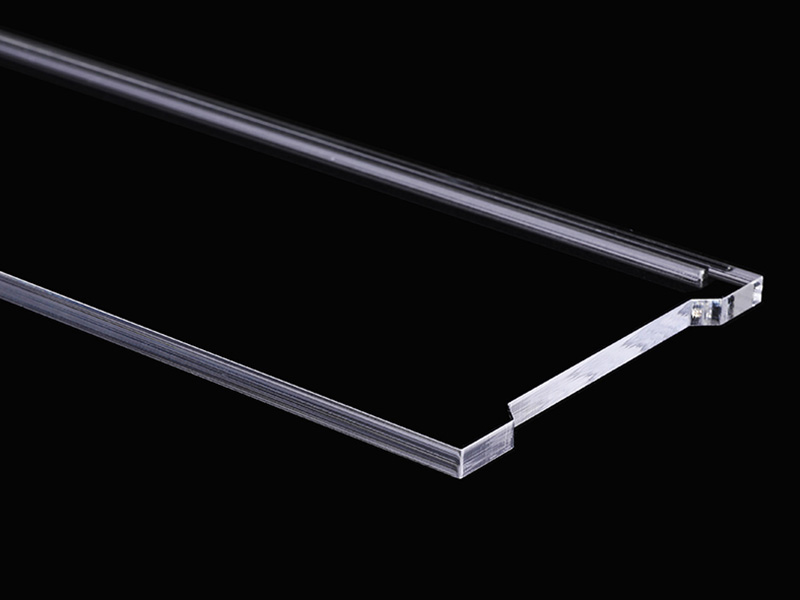

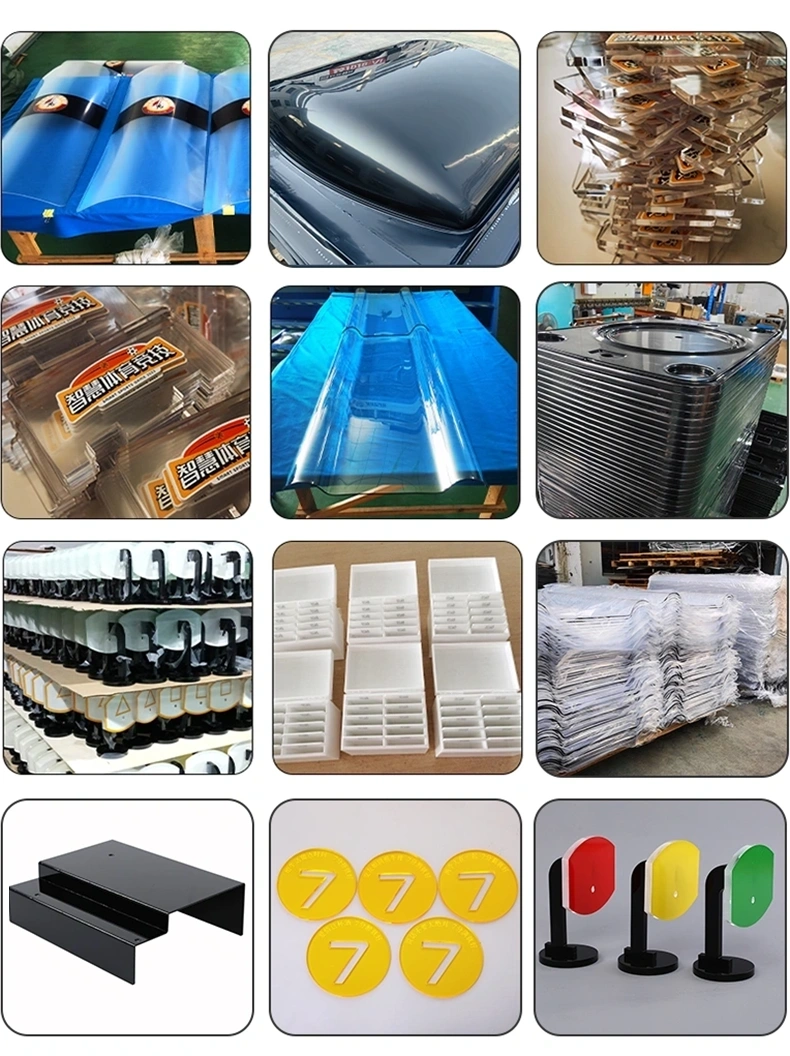

Finished Product Display

The following is only part of the finished product reference, more can consult us.

Packaging & Shipping

Wooden Case / Shockproof Foam / Protective Film

FAQ

Q1. What types of processing are suitable for PC sheets?

PC sheets are suitable for a variety of processing methods, including:

Cutting: Laser cutting, precision milling

Bending: Hot bending, cold bending

Drilling: Drilling, punching

Polishing and Grinding: Improving surface smoothness

Printing: Screen printing, UV printing

Thermoforming: Used for complex 3D shaping

Q2. What is your tolerance range?

Normally ±0.1–0.2mm depending on design.

Q3. Do you support small batches?

Yes

Q3. Do you support small batches?

Yes