Cold Bending

- Home /

- Cold Bending

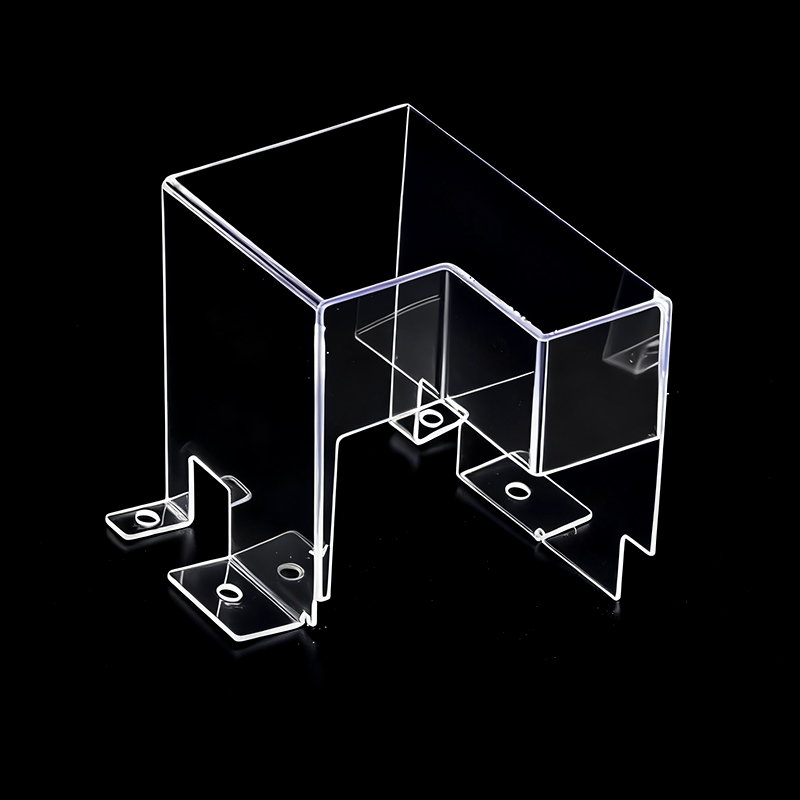

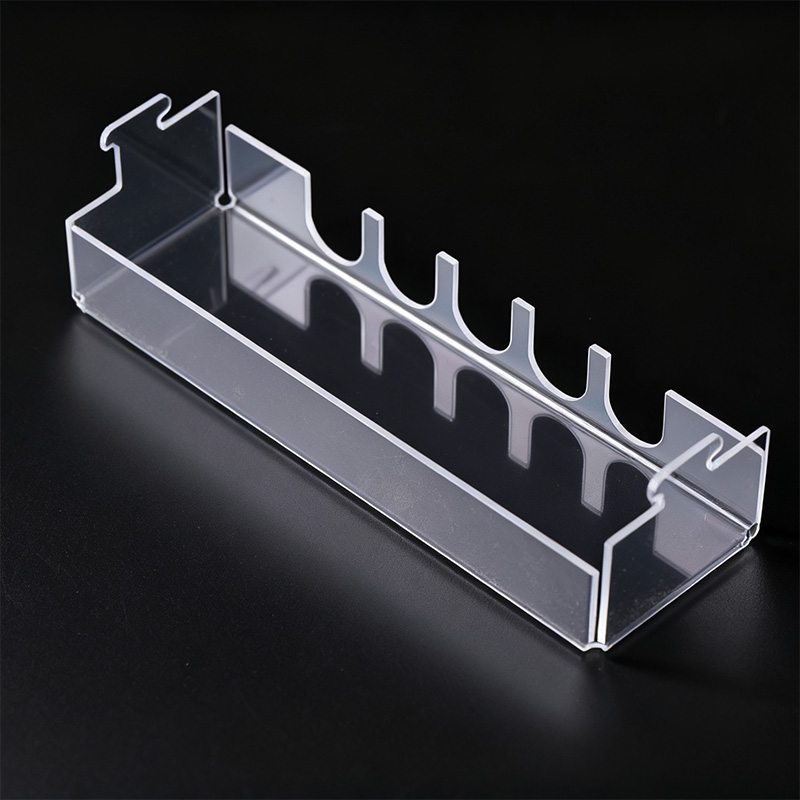

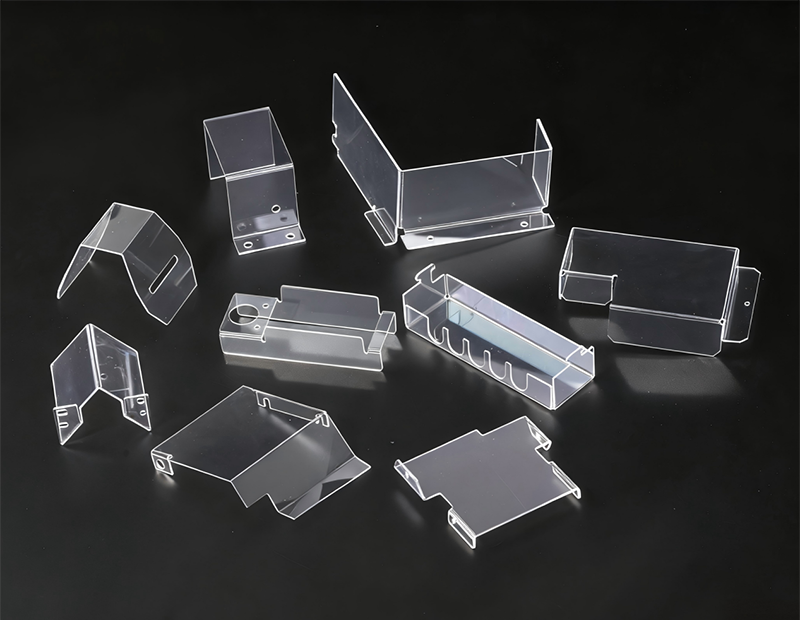

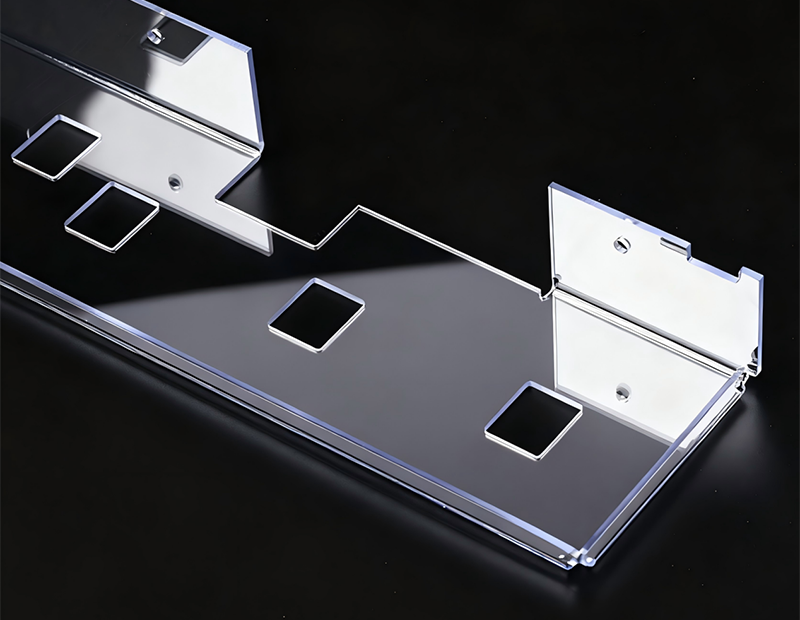

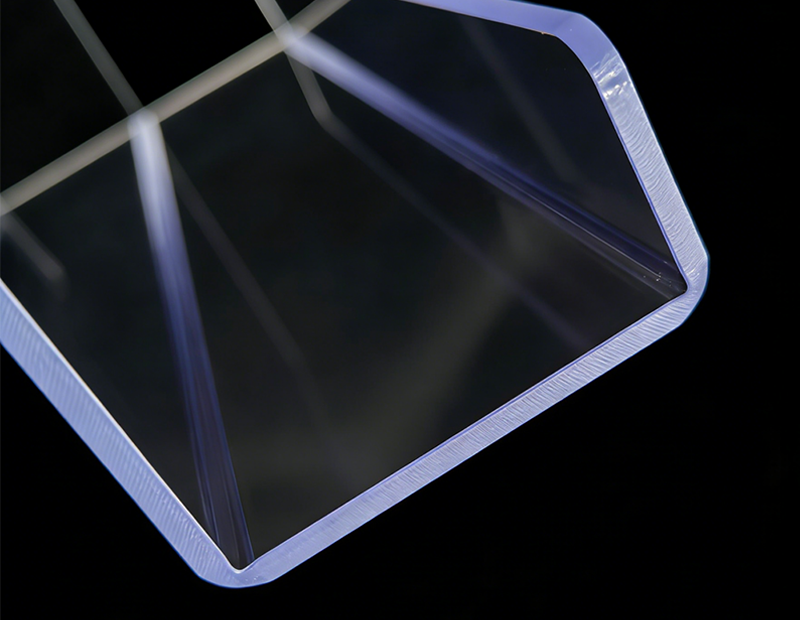

Cold Bending Services for PC & Acrylic Sheets

Cold bending is a forming process that allows plastic sheets such as polycarbonate and acrylic to be bent into shape at room temperature using controlled pressure. This method is ideal for applications that require clean, accurate bends without exposing materials to heat.

Share:

Benefits

• Precise and consistent bending angles

• No thermal stress or discoloration

• Cost-effective forming method

• Suitable for large panel bending

• Maintains excellent clarity

• Suitable for both PC and acrylic

• Ideal for protective covers and enclosures

Materials

• Polycarbonate (PC)

• Acrylic (PMMA)

• PETG

• Other engineering plastics upon request

Thickness & Size Range

Applications

• Machine guards

• Protective covers

• Equipment enclosures

• Display panels

• Light boxes

• Retail fixtures

• Barriers and shields

Technical Capability

• Single-bend & multi-bend production

• Tight tolerance control

• Smooth clean edges

• Fast turnaround for volume production

Quality & Standards

We perform strict dimensional and visual inspections to ensure accuracy, clarity and structural strength.

Why Choose Us

• 13+ years of plastic machining experience

• Advanced bending and machining equipment

• Skilled technicians

• Custom OEM & ODM support

FAQ

Q: Will cold bending affect transparency?

A: No, cold bending does not cause yellowing or optical distortion when processed correctly.