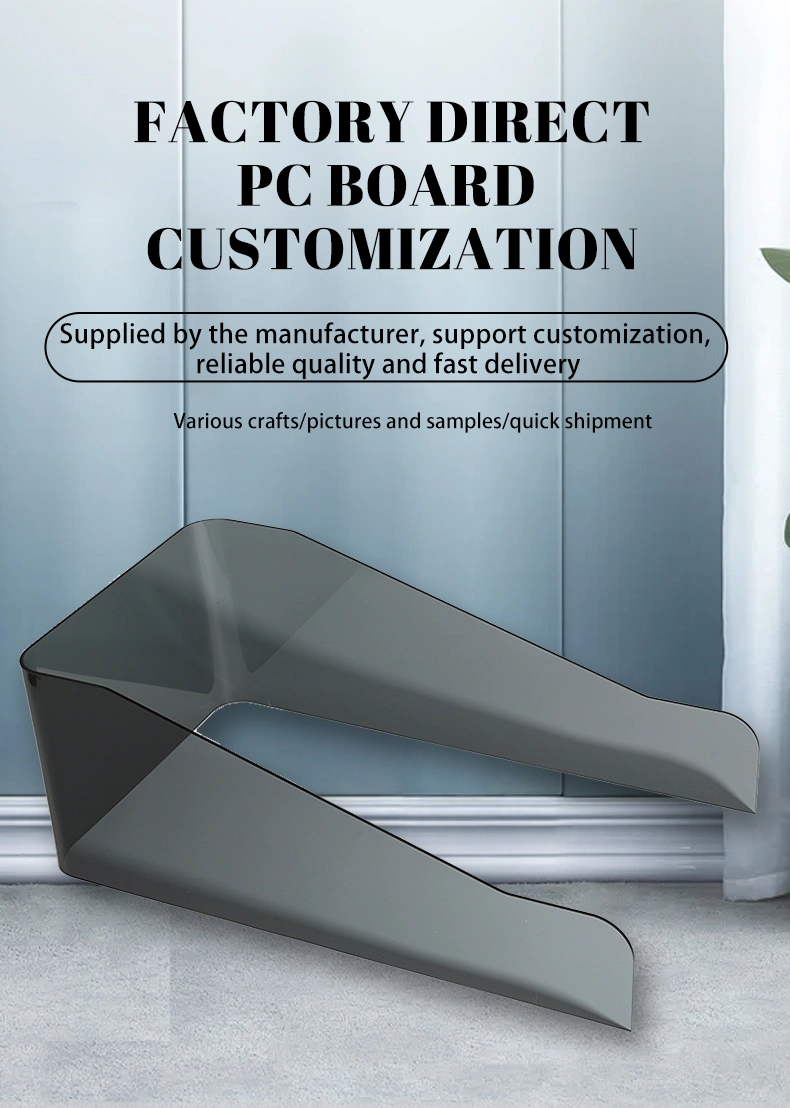

Product information

Product name | Equipment Protective Cover |

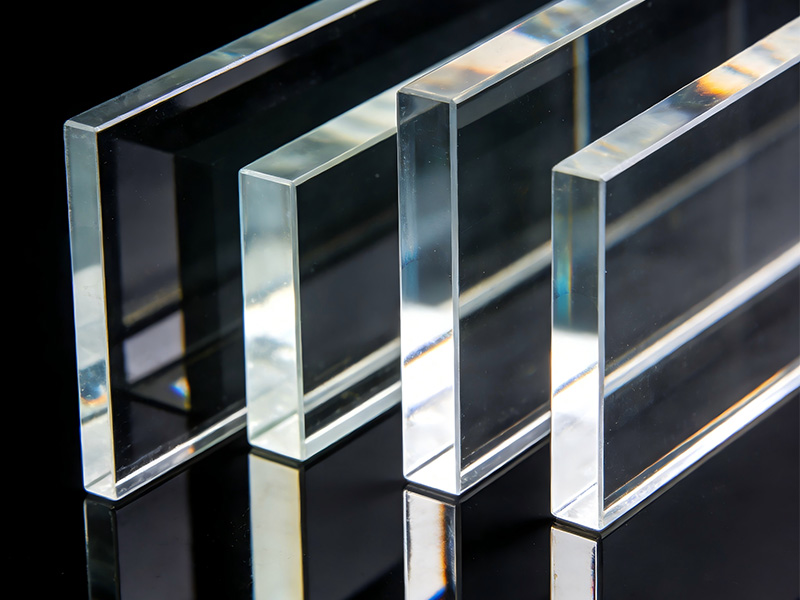

Product size | Made-to-Order Size; Thickness: 1.5mm (Customizable Thickness) |

Product color | Transparent, white, black, custom colors |

Material | Polycarbonate(PC) |

Custom | Drawing to sample/custom size/thickness |

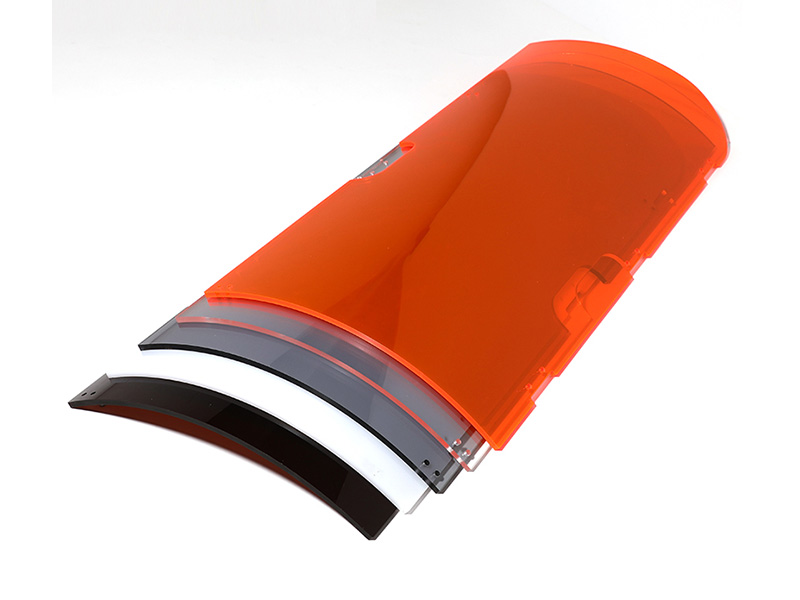

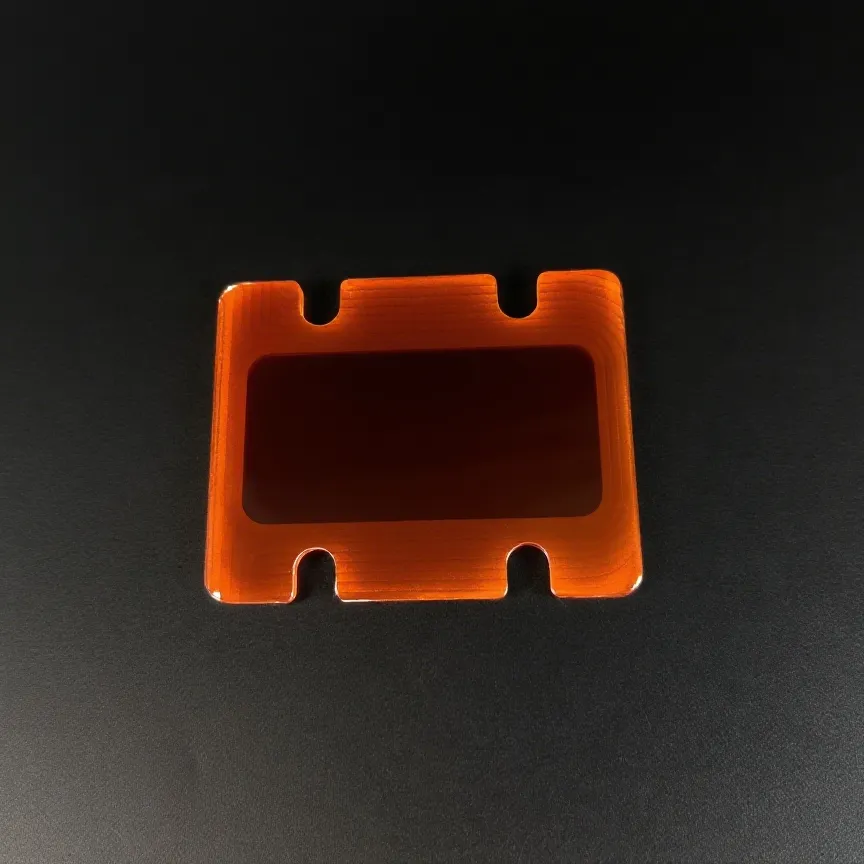

Application | Building skylights, car lamp covers, industrial protective shields, electronic device housings |

Feature | High impact resistance, excellent weather resistance, high light transmittance, wide temperature range |

Physical properties | Density: ~1.2g/cm³; Impact strength: 600-800J/m; Light transmittance: 88-90%; Working temp: -40~120℃ |

Chemical properties | Flame retardancy, chemical corrosion resistance, etc. |

Others | Flame retardant (UL94 V-0 grade), antistatic (custom),UV-resistant(custom) |

Surface | Smooth transparent/Frosted |

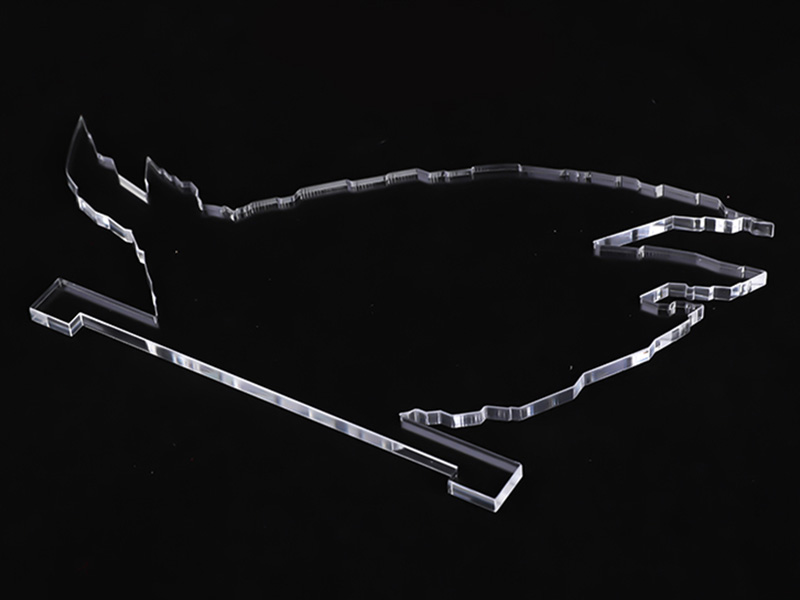

Fabrication Process | Cutting,Cold Bending,Engraving |

Technique

Production Processe

We can independently undertake the process of cutting, undercutting, milling, slotting,unching,countersinking,beveling, chamfering,brightness polishing, bending andbonding of acrylic sheet, plexiglass,PC sheet, pe sheet and pvc sheet.

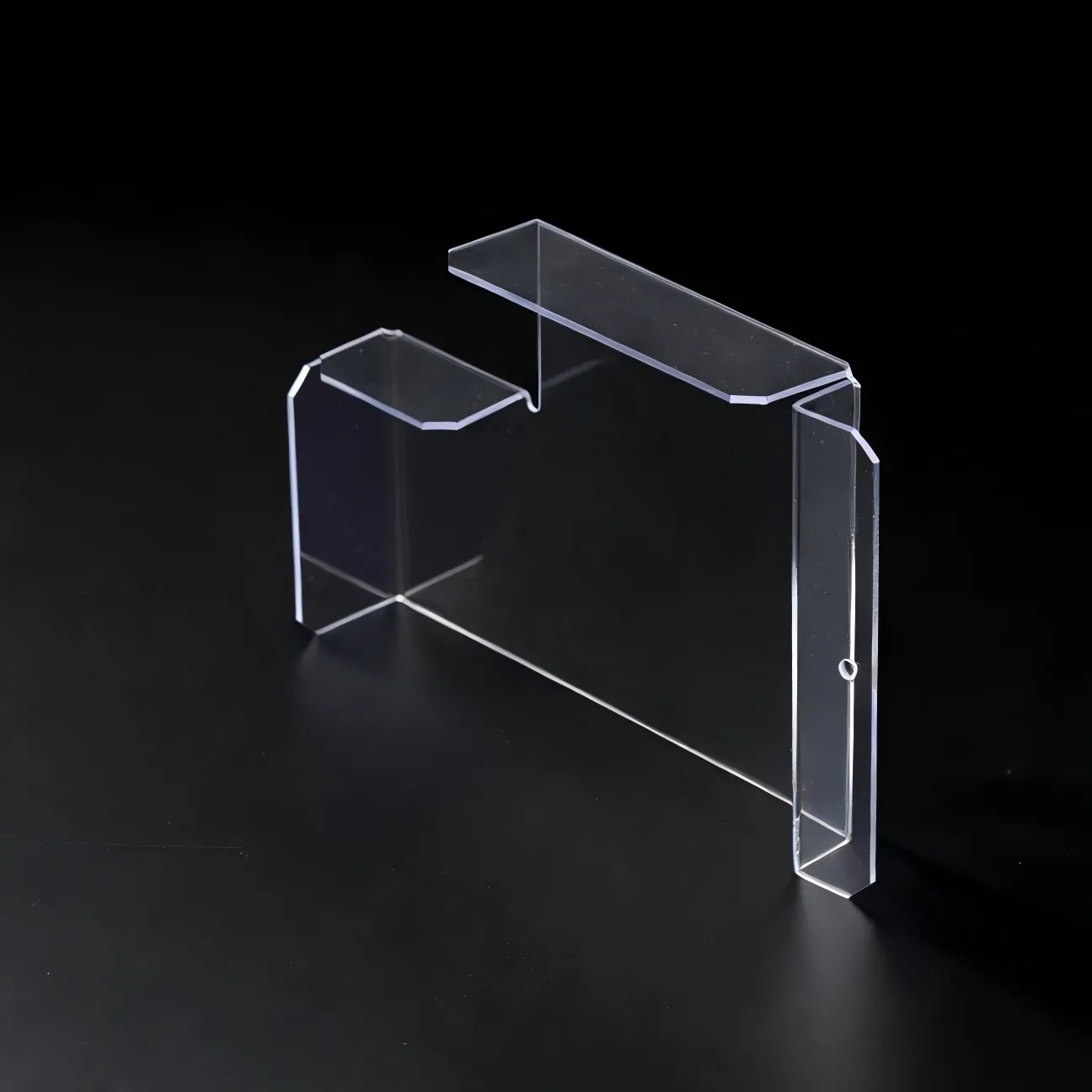

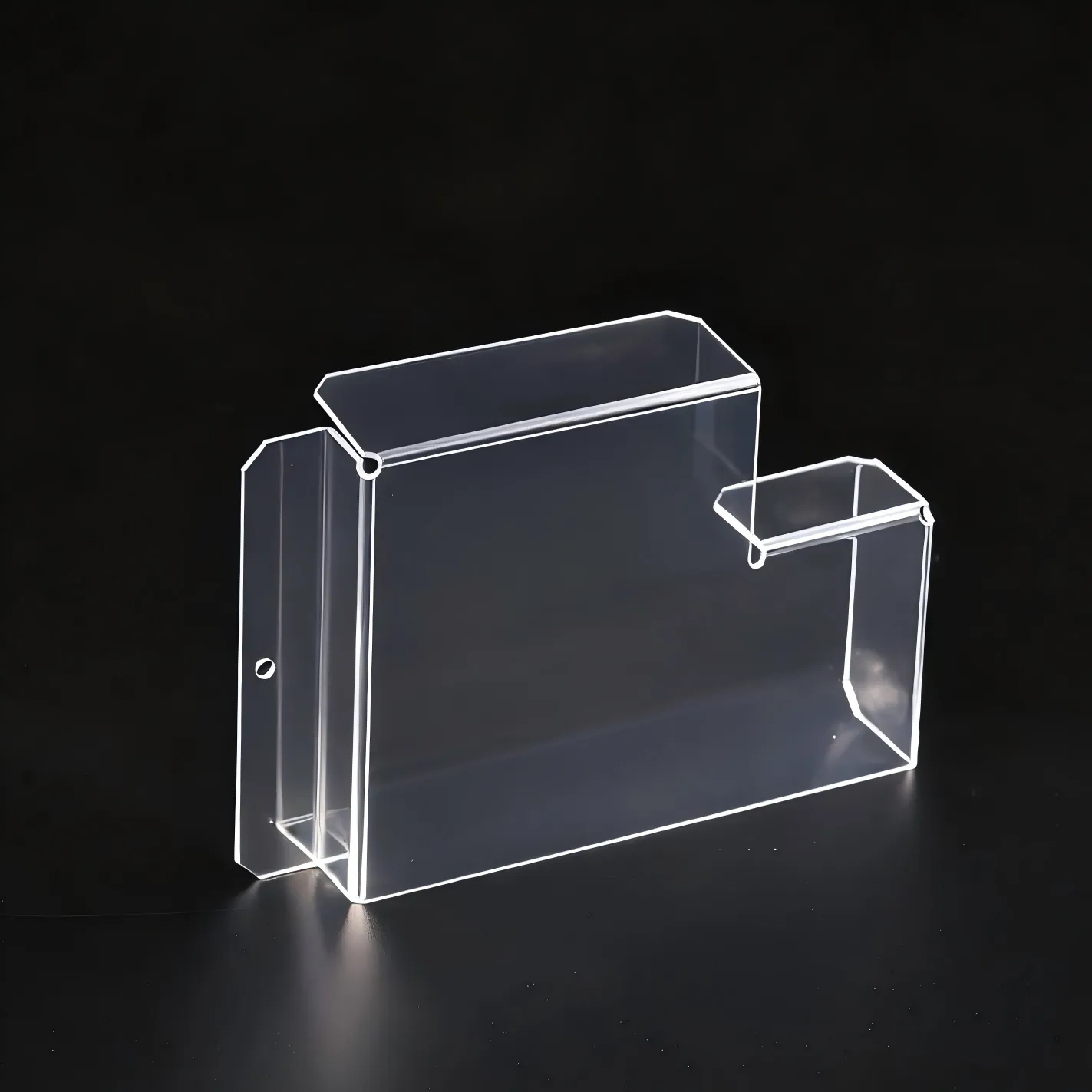

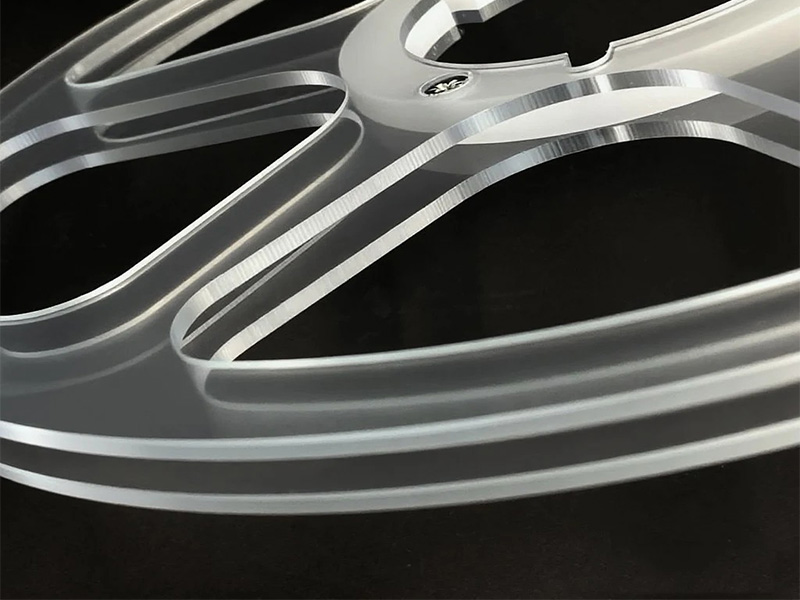

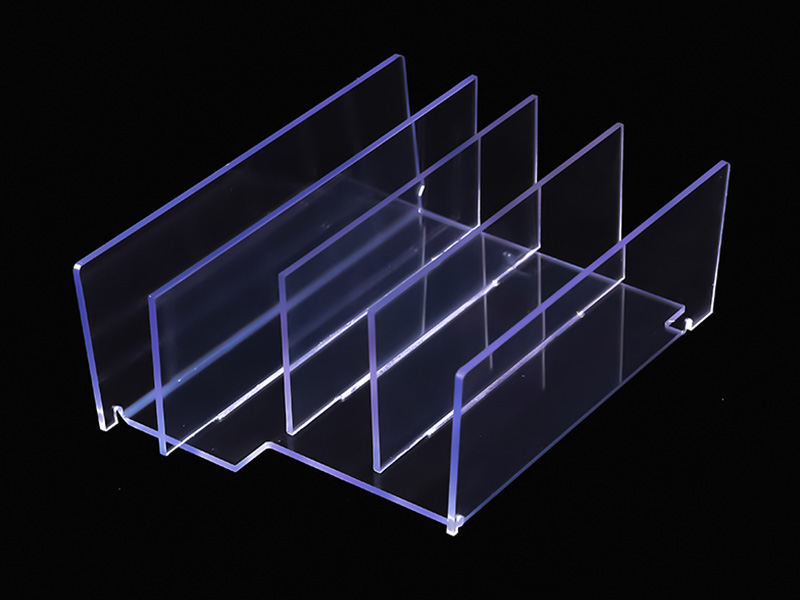

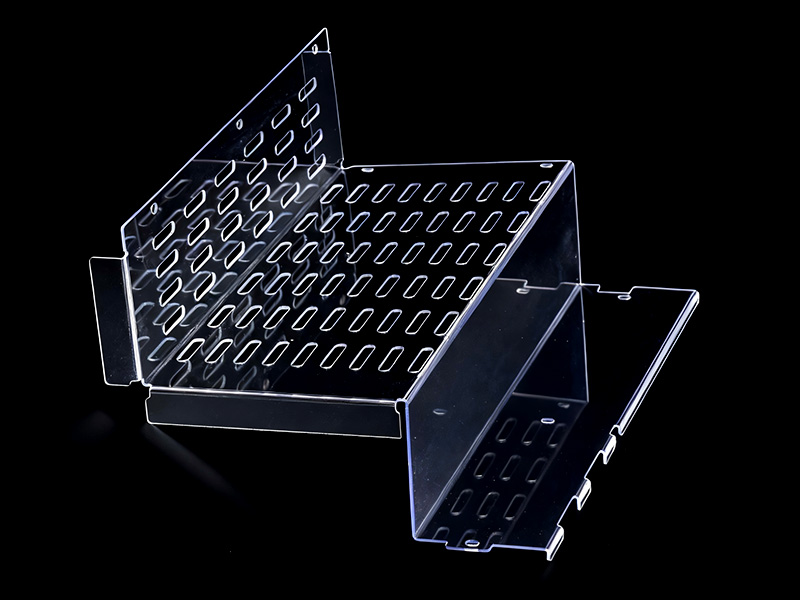

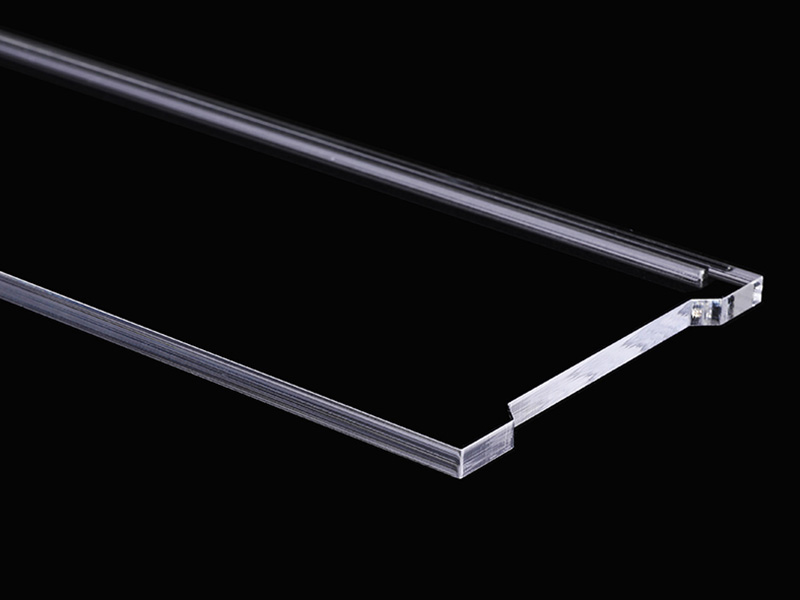

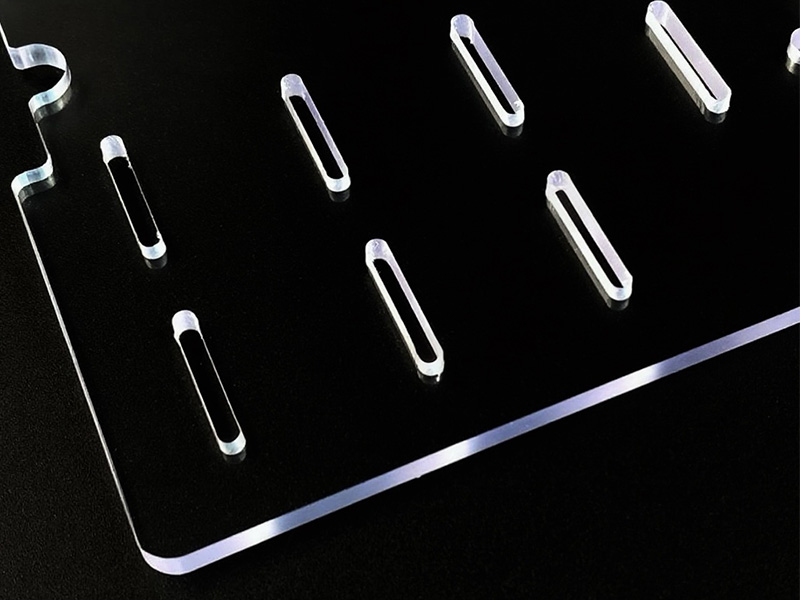

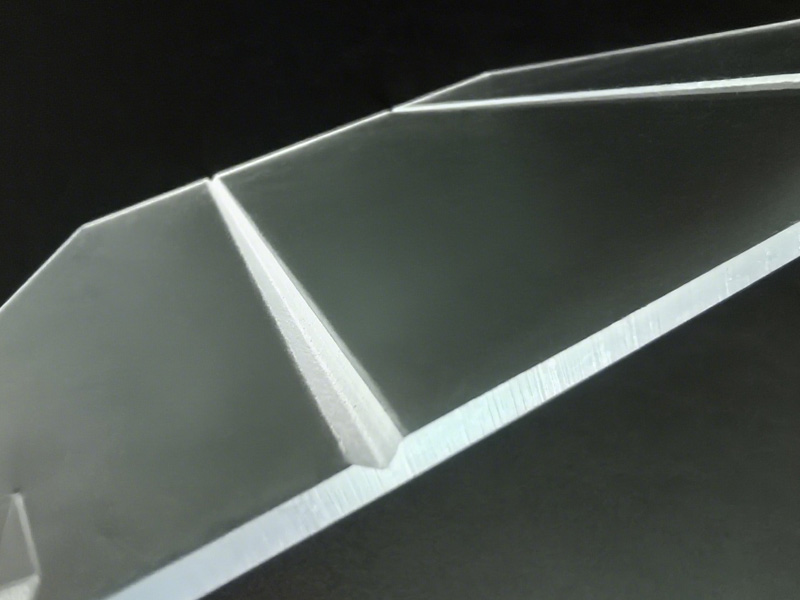

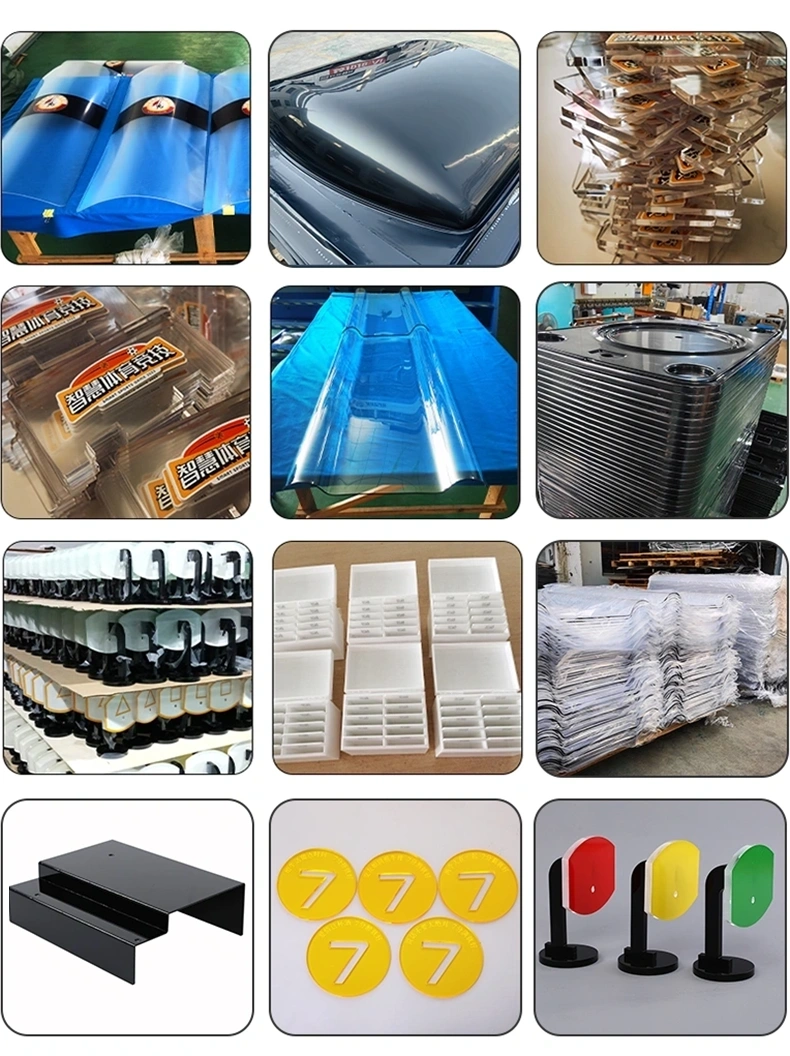

Finished Product Display

The following is only part of the finished product reference, more can consult us.

Packaging & Shipping

Wooden Case / Shockproof Foam / Protective Film

FAQ

Q1.What types of processing are suitable for PC

PC sheets are suitable for a variety of processing methods, including:

Cutting: Laser cutting, precision milling

Bending: Hot bending, cold bending

Drilling: Drilling, punching

Polishing and Grinding: Improving surface smoothness

Printing: Screen printing, UV printing

Thermoforming: Used for complex 3D shaping

Q2. How is PC sheet hot bending processed?

Hot bending of PC sheets requires heating at 150-170°C to soften the material, then bending it into the desired shape using molds or manually.

Use a hot air circulation oven or infrared heating equipment to ensure uniform temperature.

It’s important to avoid overheating during the process to prevent surface damage or color changes.

After bending, the PC sheet cools quickly and retains its shape.

Q3. What should be considered when cutting PC sheets?

The cutting of PC sheets should be done with suitable tools and methods:

Laser cutting: Suitable for thin sheets (usually <5mm), providing smooth and burr-free edges.

CNC milling: Suitable for thicker sheets, allowing for precise cutting.

Use appropriate tools to avoid overheating or discoloration during cutting.

Use dust extraction systems to prevent dust or heat from affecting the sheet surface.

Q4. What is the weather resistance of PC sheets?

PC sheets have excellent weather resistance and can withstand high temperatures, low temperatures, and UV exposure.

- However, their UV resistance is relatively poor, so it’s common to add UV coatings to enhance outdoor durability and prevent yellowing from prolonged sun exposure.

- Suitable for outdoor applications like advertising signs, protective shields, and canopies.

Q5. Are PC sheets easily scratched?

PC sheets have a relatively hard surface with good scratch resistance, but they can still be scratched or marked under strong force.

- Using a protective film can reduce scratching during processing and transportation.

- For high-demand surfaces, surface hardening treatments can enhance scratch resistance.

Q6. What are the common applications for PC sheets?

PC sheets, due to their excellent mechanical properties and transparency, are widely used in various industries:

- Construction: Transparent roofing, windows, fences

- Transportation: Car windows, vehicle interiors

- Electronics: Electronic device casings, display screen protection

- Advertising: LED light boxes, advertising signs, display racks

- Medical: Protective shields, equipment casings

Q7. Are PC sheets suitable for outdoor advertising signs?

Yes, PC sheets are commonly used for outdoor advertising signs, but attention should be paid to their UV resistance. To enhance their durability outdoors, we recommend applying UV protective coatings to prevent discoloration or degradation from prolonged sun exposure.

Q8. Will processing affect the transparency of PC sheets?

If temperature and equipment are not controlled properly during processing, it may affect the transparency of PC sheets.

- Cutting and drilling: If the tools are not sharp or the operation is improper, it may result in rough edges, surface fogging, or discoloration.

- Hot bending: If the temperature is too high or uneven, it may cause discoloration or bubbling on the surface, affecting transparency.

Q9.What is the maximum thickness of PC sheets?

PC sheets can be processed in thicknesses ranging from 0.5mm to 20mm or even thicker.

- Generally, 1mm-6mm sheets are commonly used for display racks, light boxes, and other lightweight applications.

- Thicker sheets ( >6mm) are used for heavy-duty applications like safety shields and equipment enclosures.

Q10. How do I clean PC sheets?

When cleaning PC sheets, avoid using solvents or corrosive chemicals.

- It’s recommended to use mild soap water and a soft cloth to wipe the surface.

- For stubborn stains, use a professional plastic cleaner, and avoid using hard brushes or strong cleaners.

Q11. What temperature can PC sheets withstand?

PC sheets can withstand a continuous use temperature range of -40°C to 120°C, and can briefly withstand temperatures up to 135°C.

- It has good high-temperature resistance, but prolonged exposure to high temperatures may degrade its performance.

- At very low temperatures, PC sheets may become brittle, requiring extra caution.

Q12.How clear is the optical transparency of PC sheets?

PC sheets have excellent optical clarity, with a light transmission rate of up to 88%, similar to glass transparency.

- They are suitable for applications that require high transparency, such as display panels and transparent covers.

- Transparency may change slightly after certain heat treatments or processing, so temperature control is essential.

Q13.Are PC sheets prone to cracking?

PC sheets have high toughness and are less prone to cracking, but they may crack under extreme temperatures or severe impact.

- Avoid using them in extreme conditions, such as large temperature variations or excessive bending.

- Their crack resistance can be enhanced through surface hardening treatments.

Q14. Can PC sheets be recycled?

PC sheets are recyclable and can be reused through mechanical recycling.Recycled PC material can be used to make new PC sheets or other products, reducing waste.

Q15. Do PC sheets yellow over time?

PC sheets may yellow over time if they are not treated with UV protection and are exposed to sunlight for prolonged periods.The yellowing is caused by UV radiation, which can typically be prevented by adding a UV coating.

Q16. What is the density of PC sheets?

The density of PC sheets is approximately 1.20-1.22 g/cm³, much lighter than glass while maintaining good strength and lightness.

Q17.What surface treatments are available for PC sheets?

PC sheets can be improved with various surface treatments such as coating, matte finish, or scratch-resistant treatment.

- UV Coating: Enhances weather resistance and prevents yellowing

- Scratch-resistant Coating: Improves scratch resistance, suitable for high-demand surfaces

- Matte Finish: Used for decorative purposes or to reduce gloss

Q18.Can PC sheets be painted?

PC sheets can be painted, but specialized plastic coatings are recommended.

- Primer: Use a primer designed for plastic materials to enhance adhesion.

- Coating: Use paints that are suitable for PC sheets to avoid peeling or cracking.

Q19. How is the thermal conductivity of PC sheets?

PC sheets have low thermal conductivity, approximately 0.2 W/m·K, which gives them good thermal insulation properties in high-temperature environments.

This is one of the reasons why PC sheets are often used for equipment casings, protective covers, and other products.

Q20. How impact-resistant are PC sheets?

PC sheets have extremely high impact strength, one of the highest among common plastics.Their impact resistance is 250 times that of glass.Due to their high toughness, PC sheets are perfect for products requiring high safety standards, such as protective shields, helmets, car windows, etc.