YuCheng Services

- Home /

- OEM/ODM Services

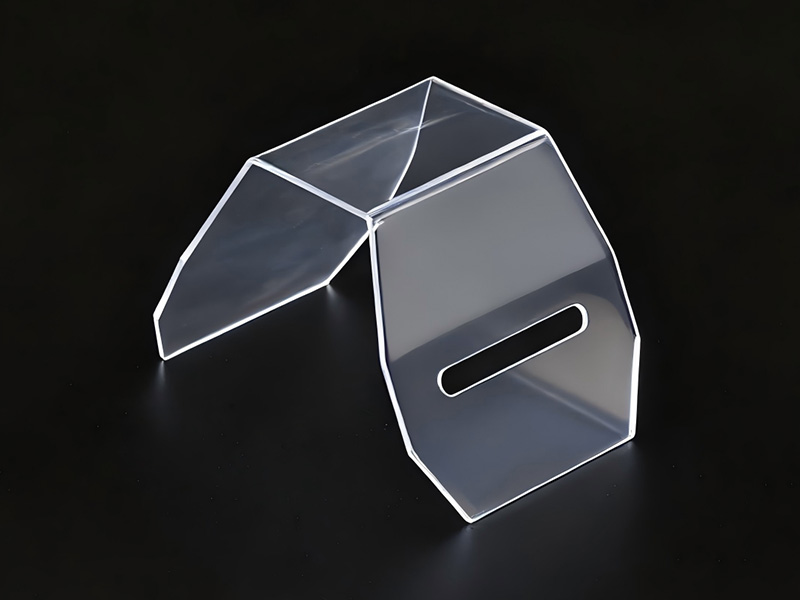

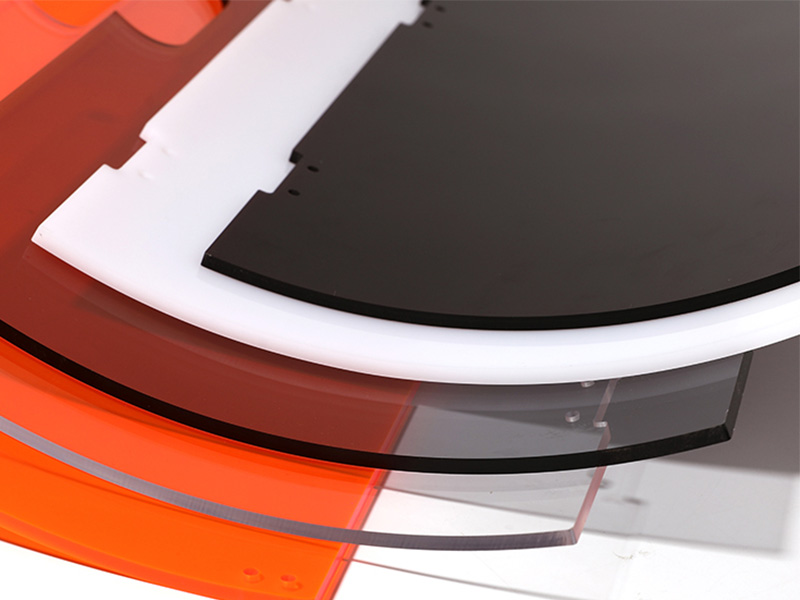

Custom PC and Acrylic Sheet Processing

We offer high-quality custom PC (Polycarbonate) and Acrylic sheet processing services to meet the unique needs of our clients. Whether you’re looking for precise cutting, bending, or complex machining, we have the technology and expertise to bring your ideas to life.

Cutting: Laser cutting, CNC milling for precise shapes and sizes.

Bending: Hot bending and cold bending for custom curves and angles.

Drilling & Punching: For customized holes or slots.

Polishing & Finishing: Smooth, polished edges for a refined look.

Engraving & Printing: UV printing and engraving for branding and design.

Advanced Fabrication Solutions

Our fabrication capabilities go beyond basic processing, offering advanced solutions that include thermoforming, surface treatments, and more. Whether it’s for industrial, commercial, or decorative applications, we ensure the highest quality standards in every project.

Thermoforming: Creating complex 3D shapes for packaging, displays, and protective covers.

Surface Treatments: UV coating, scratch-resistant coatings, matte finishes to enhance durability and appearance.

Customization: Tailored solutions based on specific project requirements, from material selection to final product design.

Prototyping and Small Batch Production

Need a prototype or a small batch of custom parts? Our team can quickly turn your design concepts into prototypes, allowing you to test and refine your products before full-scale production. We offer fast turnaround times and cost-effective solutions for prototypes and low-volume production.

Prototype Development: Fast, accurate prototypes to test your designs.

Small Batch Production: Ideal for limited runs or product testing.

Material Flexibility: We offer various thicknesses and finishes for your specific needs.

Comprehensive Design Consultation

Our team works closely with you to understand your specific needs and offer expert advice on the best material, design, and processing methods. Whether you’re designing a new product or improving an existing one, we guide you every step of the way.

Material Selection: Helping you choose the best PC or Acrylic material for your application.

Design Assistance: Offering technical expertise in product design and modification.

High-Quality Standards & On-Time Delivery

We pride ourselves on our commitment to quality. All of our products go through stringent quality control checks to ensure they meet the highest standards. With our efficient manufacturing processes, we ensure that your order is delivered on time, every time.

Quality Control: Thorough inspection and testing at each stage of production.

On-Time Delivery: Reliable and efficient production timelines.

Customer Satisfaction: Dedicated support throughout your project lifecycle.

Global Shipping & Logistics

With a strong logistics network, we provide global shipping options, ensuring that your products reach you on time and in perfect condition. We handle international orders efficiently, including customs and shipping arrangements, so you can focus on your business.

Global Reach: Serving clients worldwide with reliable shipping options.

Customs and Documentation: Handling all international shipping paperwork and customs requirements.

Safe Packaging: Ensuring your products are carefully packed to avoid damage during transit.

WHY CHOOSE US?

Expertise & Experience

With years of experience in PC and Acrylic sheet processing, we have the knowledge and skills to tackle even the most challenging projects.

Customization

We provide fully customized solutions based on your specific needs, from design to finish.

Innovation

Using the latest technology and techniques, we ensure that your products are of the highest quality and precision.

Customer-Centric Approach

Your satisfaction is our priority. We work with you to ensure your project is completed to your exact specifications.

FAQ

PC sheets are suitable for a variety of processing methods, including:

Cutting: Laser cutting, precision milling.

Bending: Hot bending, cold bending.

Drilling: Drilling, punching.

Polishing and Grinding: Improving surface smoothness.

Printing: Screen printing, UV printing.

Thermoforming: Used for complex 3D shaping.

Hot bending of PC sheets requires heating at 150-170°C to soften the material, then bending it into the desired shape using molds or manually.

Use a hot air circulation oven or infrared heating equipment to ensure uniform temperature.

It’s important to avoid overheating during the process to prevent surface damage or color changes.

After bending, the PC sheet cools quickly and retains its shape.

The cutting of PC sheets should be done with suitable tools and methods:

Laser cutting: Suitable for thin sheets (usually <5mm), providing smooth and burr-free edges.

CNC milling: Suitable for thicker sheets, allowing for precise cutting.

Use appropriate tools to avoid overheating or discoloration during cutting.

Use dust extraction systems to prevent dust or heat from affecting the sheet surface.

PC sheets have excellent weather resistance and can withstand high temperatures, low temperatures, and UV exposure.

• However, their UV resistanceis relatively poor, so it’s common to add UV coatings to enhance outdoor durability and prevent yellowing from prolonged sun exposure.

• Suitable for outdoor applications like advertising signs, protective shields, and canopies.

PC sheets have a relatively hard surface with good scratch resistance, but they can still be scratched or marked under strong force.

• Using a protective filmcan reduce scratching during processing and transportation.

• For high-demand surfaces, surface hardening treatmentscan enhance scratch resistance.

PC sheets, due to their excellent mechanical properties and transparency, are widely used in various industries:

Construction: Transparent roofing, windows, fences.

Transportation: Car windows, vehicle interiors.

Electronics: Electronic device casings, display screen protection.

Advertising: LED light boxes, advertising signs, display racks.

Medical: Protective shields, equipment casings.

Yes, PC sheets are commonly used for outdoor advertising signs, but attention should be paid to their UV resistance. To enhance their durability outdoors, we recommend applying UV protective coatings to prevent discoloration or degradation from prolonged sun exposure.

If temperature and equipment are not controlled properly during processing, it may affect the transparency of PC sheets.

Cutting and drilling: If the tools are not sharp or the operation is improper, it may result in rough edges, surface fogging, or discoloration.

Hot bending: If the temperature is too high or uneven, it may cause discoloration or bubbling on the surface, affecting transparency.

PC sheets can be processed in thicknesses ranging from 0.5mm to 20mm or even thicker.

• Generally, 1mm-6mmsheets are commonly used for display racks, light boxes, and other lightweight applications.

• Thicker sheets ( >6mm) are used for heavy-duty applications like safety shields and equipment enclosures.

When cleaning PC sheets, avoid using solvents or corrosive chemicals.

• It’s recommended to use mild soap waterand a soft cloth to wipe the surface.

• For stubborn stains, use a professional plastic cleaner, and avoid using hard brushes or strong cleaners.

PC sheets can withstand a continuous use temperature range of -40°C to 120°C, and can briefly withstand temperatures up to 135°C.

• It has good high-temperature resistance, but prolonged exposure to high temperatures may degrade its performance.

• At very low temperatures, PC sheets may become brittle, requiring extra caution.

PC sheets have excellent optical clarity, with a light transmission rate of up to 88%, similar to glass transparency.

• They are suitable for applications that require high transparency, such as display panels and transparent covers.

• Transparency may change slightly after certain heat treatments or processing, so temperature control is essential.

PC sheets have high toughness and are less prone to cracking, but they may crack under extreme temperatures or severe impact.

• Avoid using them in extreme conditions, such as large temperature variations or excessive bending.

• Their crack resistance can be enhanced through surface hardening treatments.

PC sheets are recyclable and can be reused through mechanical recycling.

• Recycled PC material can be used to make new PC sheets or other products, reducing waste.

• During recycling, it’s important to sort, clean, and remove contaminants.

PC sheets may yellow over time if they are not treated with UV protection and are exposed to sunlight for prolonged periods.

• The yellowing is caused by UV radiation, which can typically be prevented by adding a UV coating.

• Choosing high-quality PC sheets can effectively prevent yellowing.

The density of PC sheets is approximately 1.20-1.22 g/cm³, much lighter than glass while maintaining good strength and lightness.

This density offers a good balance between weight and strength.

PC sheets can be improved with various surface treatments such as coating, matte finish, or scratch-resistant treatment.

UV Coating: Enhances weather resistance and prevents yellowing.

Scratch-resistant Coating: Improves scratch resistance, suitable for high-demand surfaces.

Matte Finish: Used for decorative purposes or to reduce gloss.

PC sheets can be painted, but specialized plastic coatings are recommended.

Primer: Use a primer designed for plastic materials to enhance adhesion.

Coating: Use paints that are suitable for PC sheets to avoid peeling or cracking.

For large-scale painting, it is recommended to first sand the surface to improve adhesion.

PC sheets have low thermal conductivity, approximately 0.2 W/m·K, which gives them good thermal insulation properties in high-temperature environments.

This is one of the reasons why PC sheets are often used for equipment casings, protective covers, and other products.

PC sheets have extremely high impact strength, one of the highest among common plastics.

• Their impact resistance is 250 times that of glass, making them suitable for applications that require high impact resistance, such as protective shields, helmets, car windows, etc.

• Due to their high toughness, PC sheets are perfect for products requiring high safety standards.