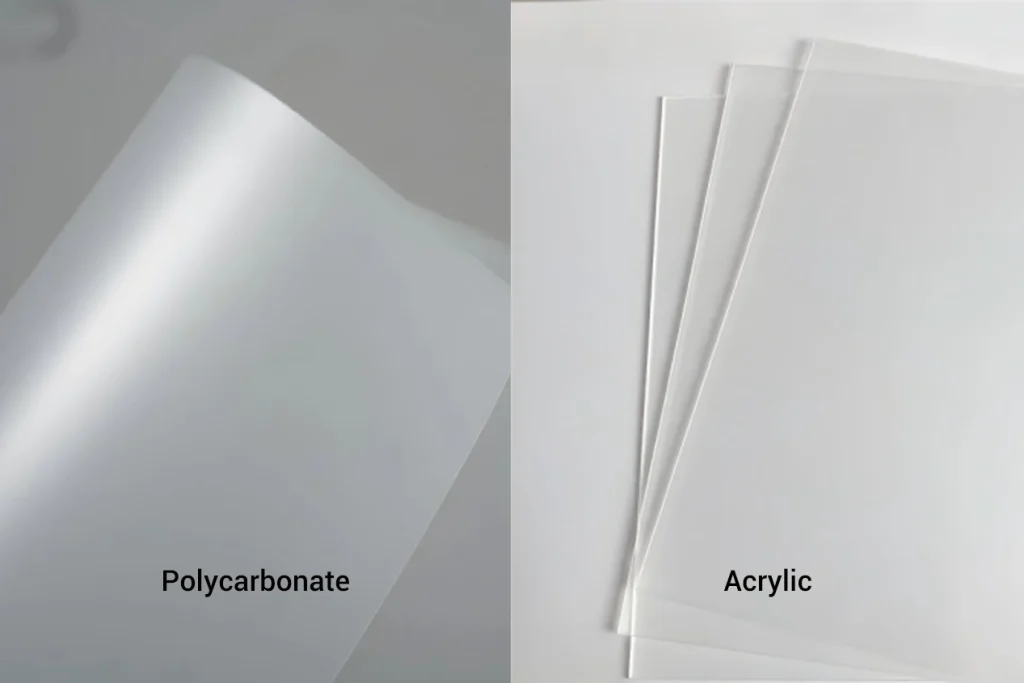

When planning a project that requires durable, transparent, or lightweight plastic sheets—such as signage, display cases, or industrial enclosures—two materials often stand out: Polycarbonate (PC) sheets and Acrylic (PMMA) sheets.

Although both offer excellent transparency and versatility, each material has unique performance characteristics that make it suitable for different applications. Understanding their differences is key to avoiding unnecessary costs, performance issues, or project delays.

In this guide, we break down the essential comparisons between PC sheets and Acrylic sheets to help you select the most suitable option for your project.

Quick Decision Guide: PC vs. Acrylic — Comparison Table

| Property | Polycarbonate (PC) | Acrylic (PMMA) | Recommended Use |

| Core Features | Exceptional impact resistance; outstanding toughness | Excellent optical clarity; superior surface hardness | PC → “Safety Expert”; Acrylic → “Optical Specialist” |

| Impact Resistance | Very high (250× stronger than glass; 10× stronger than acrylic) | Moderate; prone to cracking under strong impact | PC is ideal for protective applications requiring impact resistance, such as equipment guards |

| Optical Performance | Good (light transmittance 88–90%), but long-term outdoor use may slightly yellow | Excellent (light transmittance up to 92%); clearer and more transparent | Acrylic is better for transparent display windows, light guides, etc. |

| Temperature Resistance | High (continuous use −40°C to 135°C), UL94 V-0 flame rating available | Moderate (continuous use −20°C to 95°C), flammable | PC is preferred in high-temperature environments or scenarios requiring flame retardancy |

| Processing Performance | Good machinability; suitable for CNC, drilling, bending, thermoforming | Easy to cut, bend, polish, laser cut | Acrylic is ideal for projects requiring high optical clarity and precise detailing |

| Weatherability | Good (with UV coating); may yellow after long-term outdoor exposure | Excellent (UV-resistant versions available) | For long-term outdoor clarity, acrylic is generally better |

| Weight | Similar | Similar | — |

| Cost | Higher | Moderate; more cost-effective | Acrylic is more budget-friendly; PC offers durability worth the investment |

1. Durability & Impact Resistance: PC Sheets Lead the Way

The most significant difference between the two materials lies in impact strength—a critical factor for high-traffic or high-risk environments:

PC Sheet:

Known as the “unbreakable plastic,” polycarbonate offers impact resistance 250× stronger than glass and 10× stronger than acrylic. It withstands strong impacts—such as dropped tools in industrial settings or accidental collisions in public spaces—without cracking or shattering. This makes PC the preferred choice for projects that prioritize safety and long-term durability.

Acrylic Sheet:

While acrylic is hard and more scratch-resistant (especially with surface coatings), it is more brittle compared to PC. It may crack or break under moderate impact, making it better suited for low-risk indoor environments such as display stands or decorative signage where the chance of physical damage is minimal.

2. Transparency & Optical Performance: Acrylic Is the Clear Winner

If your project relies on visual clarity or premium aesthetics, optical properties become the top concern:

Acrylic Sheet:

Acrylic provides up to 92% light transmittance—higher than PC (88%) and close to glass (90%). It maintains clarity over time (especially UV-resistant grades) and offers sharp, crisp visual presentation. This makes it ideal for retail display cases, museum exhibits, lighting diffusers, and any application where clarity enhances the final product.

PC Sheet:

While still highly transparent, polycarbonate may carry a slight bluish tint (often unnoticeable) and, without UV protection, can yellow faster under direct sunlight. It is most suitable for projects where durability outweighs the need for perfect clarity, such as outdoor machine guards or protective barriers.

3. Temperature Resistance: PC Performs Better in Extreme Environments

For projects exposed to high or low temperatures, heat resistance plays a vital role:

PC Sheet:

Polycarbonate withstands continuous temperatures up to 120°C (248°F) and remains stable at temperatures as low as −40°C (−40°F) without becoming brittle. It is ideal for outdoor applications—such as signage and greenhouse panels—as well as industrial uses near heat sources, including electrical housings.

Acrylic Sheet:

Acrylic offers lower heat resistance, with a maximum continuous use temperature of 80°C (176°F). It may soften or deform under high heat and can crack under force in freezing conditions. It is best suited for indoor applications or outdoor uses with minimal temperature fluctuations, such as shaded signage.

4. Processing Difficulty & Cost: Acrylic Is Easier and More Cost-Effective

For small orders or projects with tight budgets, cost-effectiveness and processing flexibility are key:

Acrylic Sheet:

Acrylic is easier to cut, drill, polish, and thermoform—even with basic tools. It also costs less per square meter than PC. This makes it ideal for startups, small businesses, or projects requiring complex designs, such as decorative acrylic letters or custom display stands—situations where cost and flexibility are priority factors.

PC Sheet:

Polycarbonate requires more specialized tools and skills to prevent edge cracks during processing. It also has a higher material cost due to its superior performance. However, for large-scale or high-risk applications—such as safety guards or outdoor canopies—the durability justifies the investment.

5. Environmental Resistance: Each Material Has Its Own Strengths (with Proper Treatment)

UV Resistance:

Both materials can resist UV damage when properly treated. UV-coated acrylic maintains long-term clarity better under direct sunlight, while UV-stabilized PC resists yellowing and maintains structural integrity outdoors.

Chemical Resistance:

Acrylic performs better against weak chemicals such as detergents, whereas PC is more resistant to stronger industrial solvents.

When to Choose Polycarbonate (PC):

Choose PC if your main requirements include:

• Safety & High Durability: Machine guards, protective shields, safety barriers, anti-riot equipment, helmet visors.

• High Impact Resistance: Retail fixtures in high-traffic areas, anti-vandal glazing, sports equipment.

• High-Temperature Stability: LED light diffusers, automotive components, medical device housings requiring high-temperature sterilization.

When to Choose Acrylic (PMMA):

Choose acrylic if your priority is:

• Optical Clarity & Aesthetics: Retail display cases, museum showcases, trophies, decorative panels, signage, aquarium windows.

• Cost-Effective Weather Resistance: Outdoor signage (with UV coating), skylight domes, architectural décor.

• Ease of Processing & Fine Detail: Complex thermoformed shapes, precise laser-cut lettering, edges polishable to crystal-clear finish.

How to Choose: A Quick Decision Guide

| Project Type | Recommended Material | Key Reason |

| Outdoor Safety Guardrail | PC Sheet | High impact resistance & temperature resistance |

| Indoor Retail Display Cabinet | Acrylic Sheet | Ultra-high transparency & lower cost |

| Industrial Machine Enclosure | PC Sheet | Chemical resistance & impact strength |

| (Indoor) Decorative Signage | Acrylic Sheet | Easy to process & visually clear |

| Temperature Control Panel | PC Sheet | Extreme temperature resistance & impact resistance |

Expert Advice: The Power of Working With a Knowledgeable Manufacturer

Even the best material choice can fail if it is not processed correctly.

Polycarbonate requires proper tooling and annealing to prevent stress cracking, while acrylic needs precise temperature control during bending to maintain clarity.

As a one-stop PC & acrylic fabrication factory, we don’t just supply materials — we help you choose the right material for your project. Our team can provide samples, share industry-specific insights, help you select the proper grade (such as UV-resistant or anti-static sheets), and customize a fabrication plan based on your chosen material.

Contact us today to discuss your project needs. Let us turn your ideas into reality with the most suitable polycarbonate or acrylic solution.